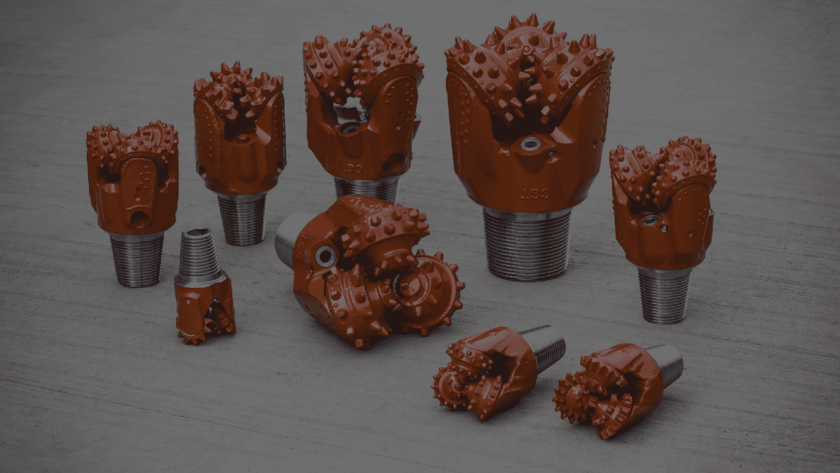

D rilling technology has come a long way over the years, and Ryder Drilling is proud to offer the latest innovation in the drilling industry: the RC Hammer. This drilling tool is the perfect solution for those looking to drill through tough, tough rock more efficiently and cost-effectively. Here are some of the benefits of…